Why Digital Fabrication Skills Matter

It might seem weird that a company that offers Software Development and Cybersecurity Services puts out posts about digital fabrication. But here's why I think it matters.

Back in the day, subsistence farmers could get by with what they had on hand. They were pretty self-sufficient, crafting and/or repairing most of their daily necessities either on their own land or sourcing them locally. The technology and tools of the time were simple enough that you could manage without relying too heavily on outside resources. The good old "Number 8 wire mentality" - that Kiwi ingenuity that says, "If it's broken, we'll fix it with what we've got" is a source of national pride in NZ. It's about making do, being resourceful, and not being afraid to roll up your sleeves and give it a go.

Then came the industrial revolution and suddenly, we found ourselves "needing" all sorts of fancy gadgets and gizmos that required specialist manufacturing. To take advantage of economies of scale, this shift pushed production into massive, centralised factories, and our self-sufficiency took a hit.

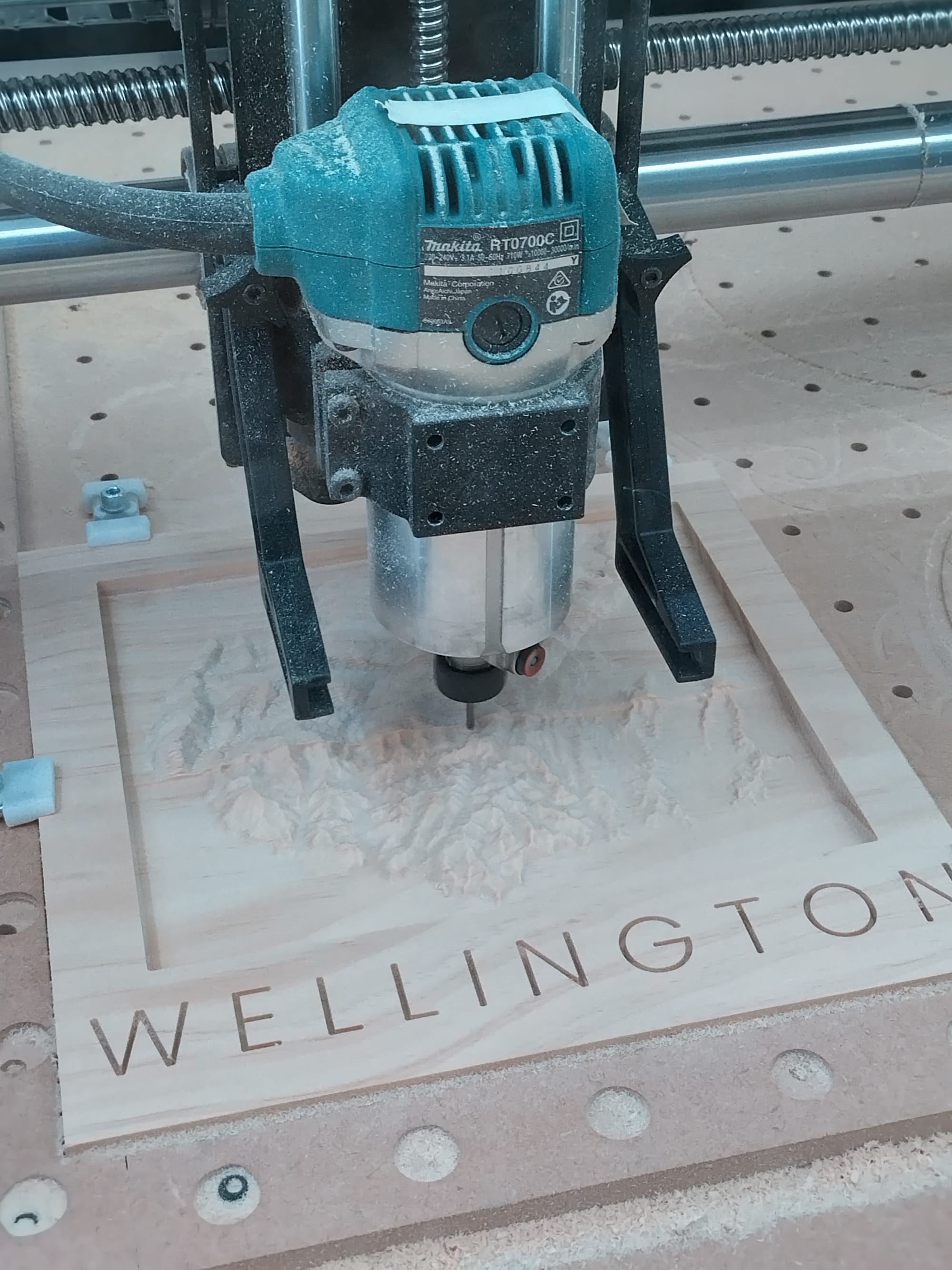

But it seems that just as swiftly, we now enter the age of digital fabrication. As this technology matures and becomes more affordable, we're seeing a return to a kind of modern self-sufficiency. Everyday folks like you and me can now manufacture some pretty complicated stuff right from our own homes. When I look across the array of tools accumulated in my garage, I see many of the standard items that generations before me would have turned to. Screwdrivers, pliers, saws and spanners. But I can't help but notice the CNC router in the corner and then turn my attention towards a gap where one day I plan to house a 3d printer and a maybe even a laser cutter after that.

I think 3d printers are absolutely amazing and am always astounded by the creativity of projects in which they are put to use which is why I'm excited for it to be the next addition to my home workshop. They can churn out complex shapes in all sorts of materials, many of which would be impossible to make any other way. But I'm especially interested when I see them used to facilitate small scale batch manufacturing. What do I mean by that? Well, you can use a 3d printer to make reusable moulds that can then be used for vacuum forming or even forging carbon fibre parts for example.

Long video but skim through it and you'll get the idea.

Mind-blowing hey?

CNC routers can even carve out circuit boards for use in electronics projects too.

Speaking of electronics, this is a space I'd say we're currently in a "semi-self-sufficient" era. Many of the individual components used in electronics still require complex manufacturing not currently possible in a home workshop. But the average home workshop can stock up on the generic "building blocks" of electronics projects with a few Raspberry Pis, Arduinos, and a smorgasbord of sensors, servos, motors, and lights. If you keep a handful of these in hand, you've got the ability to cobble together all kinds of DIY electronics projects that are often much more affordable than products purchased off the shelf.

Where am I going with all this?

Why does any of this even matter?

Well, most of us can think of a time where someone of an older generation scorned the practical abilities of a youngster. "That young bloke couldn't swing a spanner to save his life!". There was an expectation that to be a competent adult, that you could at least turn your hand to a DIY project using a basic set of tools. But nowadays, I believe that this skillset is expanding and that we should aim towards a state of play where kids can turn their hand to basic digital fabrication too.

Why? Well, because the skills acquired in these endeavours spill over into your professional life too. A youngster entering the workforce who's grown up tinkering in a tech infused home workshop will inevitably have dabbled in coding & CAD/CAM along the way and is likely to be much more I.T. literate. They're also far more likely to have solid foundational STEM understanding and better critical thinking abilities. Regardless of your chosen profession, these days all of the above mentioned skillsets are a requirement.

In business, we're often faced with the daunting challenge of deciding which technology platform we'll adopt to run our day to day operations. In most cases, there will be options that are completely "turnkey". You pay your monthly subscription and it "just works". But over time, these subscriptions add up and can quickly become an expensive mountain of monthly recurring bills. There's a hidden cost to not understanding technology that runs these products.

But if you've got the digital "number 8 mentality", there are often free open source alternatives that are far, far more affordable. However, they'll almost always require more technical understanding to get them up and running.

So it's my contention that if we want to keep all these Silicon Valley tech bros honest, we need to make sure we've all got enough technical nous to know when to ditch the subscriptions and build our own solutions. And attaining that understanding? Well, I believe the most fun and engaging way to learn all this starts with spending some time tinkering in a digitally enabled home workshop, where the Number 8 wire of yesterday meets the 3D printer of tomorrow.